Material selection and durability are two crucial considerations before making luggage accessories. These factors not only directly affect the quality and performance of the product, but also determine its competitiveness in the market and consumer satisfaction. It is essential to develop a clear strategy to ensure efficient material selection and long-lasting durability of the product.

Material selection is the basis for determining the quality of luggage accessories. Different types of materials have different properties, such as leather, polyester, canvas, and nylon. Leather is known for its luxury and durability, but its cost is high and processing is complicated; while polyester is popular for its lightness and economy, but it is slightly inferior in abrasion resistance and high temperature resistance. When choosing materials, you need to consider the target market, budget, and the purpose of the product. Materials used for travel bags need to have high strength and tear resistance, while materials used for fashion handbags may focus more on appearance and touch.

The quality of the material is the key to ensuring durability. Even if the right material is selected, if its quality is not up to standard, it may cause problems during the use of the product. Low-quality fabrics may pill or crack easily, while inferior hardware accessories may rust or deform easily. When purchasing materials, suppliers must be strictly screened and the performance of the materials must be tested to ensure that they meet the design requirements. It is also necessary to consider the environmental friendliness and sustainability of the materials. As consumers pay more and more attention to environmental issues, the use of recyclable or degradable materials will become a competitive advantage.

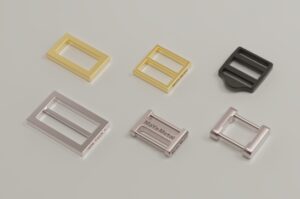

Based on the selection of materials, durability is a core element that cannot be ignored in the design of luggage accessories. Durability is not only reflected in the material itself, but also in the structural design and manufacturing process of the product. The fineness of the sewing process directly affects the load-bearing capacity of the product, and the use of reinforcement strips can effectively extend the service life of the product. The selection of hardware accessories is also crucial. Parts such as zippers, buttons and handles need to have high strength and durability to ensure that the product will not fail during long-term use.

The coordination of color and texture is also a factor that needs to be considered. Although these factors are not directly related to durability, they will affect the aesthetics and market appeal of the product. Dark materials are generally less likely to show dirt, while bright colors may fade more easily. When selecting materials, it is necessary to comprehensively consider the stability of color and texture to ensure that the product maintains a good appearance during use.

Cost and budget are also important factors that need to be weighed. High-quality materials and complex manufacturing processes often mean higher costs, while too low costs may lead to reduced product quality. In the material selection and design process, it is necessary to find a balance between performance, aesthetics and cost to ensure that the product can both meet consumer needs and be competitive in the market.

Before making luggage accessories, material selection and durability are two aspects that need to be considered. By comprehensively considering the performance, quality, aesthetics and cost of materials, products that are both practical and competitive in the market can be designed. As consumers’ requirements for quality and environmental protection continue to increase, the design and manufacture of luggage accessories in the future need to pay more attention to sustainability and innovation to meet the changing market needs.