The manufacturing processes for stainless steel hardware accessories (e.g., zippers, buckles, handles) in luggage and bags include:

1. **Stamping**

– High-precision molds shape metal sheets into components.

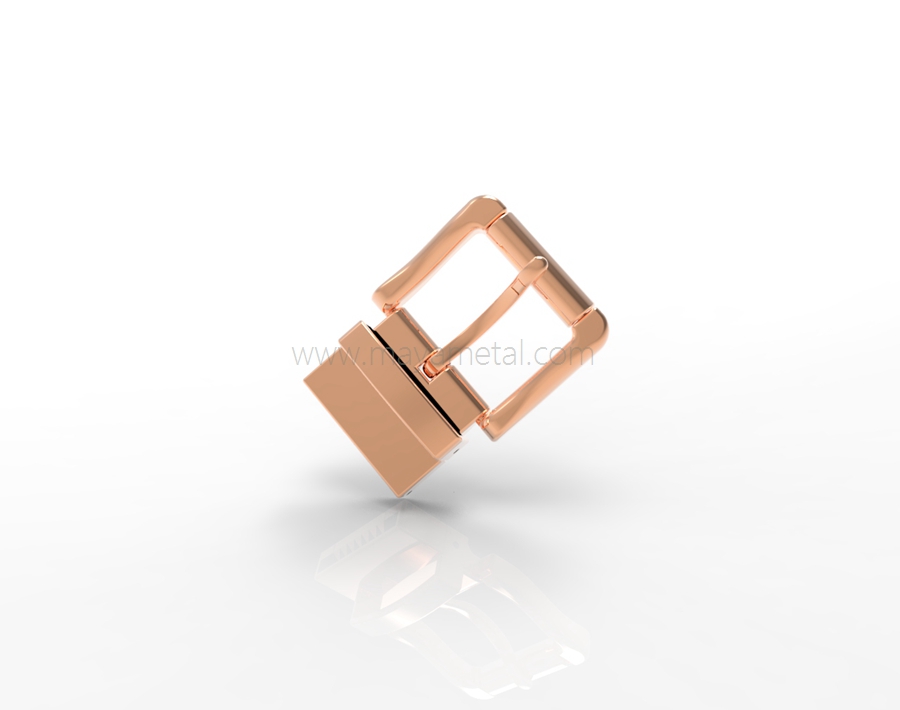

2. **Casting**

– Molten stainless steel is poured into molds for complex designs (e.g., decorative clasps).

3. **CNC Machining**

– Computer-controlled cutting ensures accuracy for hinges and locks.

4. **Polishing**

– Mechanical or manual polishing creates smooth, scratch-resistant surfaces.

5. **Electroplating**

– Adds coatings (e.g., nickel, PVD gold) for corrosion resistance and aesthetics.

6. **Laser Engraving**

– Custom logos or patterns are etched onto surfaces.

7. **Assembly**

– Components are riveted, welded, or screwed into finished products.

**Key Technologies**:

– Precision tooling for consistency in mass production.

– Salt-spray testing to ensure rust resistance.

– Eco-friendly electroplating to meet international standards (e.g., REACH).